In 1913 the Fairgrieve brothers travelled to the United States to learn about the production of Bakelite plastic. At that time, Bakelite was used in almost every manufactured product that required thermal properties, strength, and rigidity. It is still used in many applications today. The brothers would use that knowledge to establish Fairgrieve Brothers, becoming one of the first companies in the UK to specialise in the production of parts made from this pioneering development in plastics. The business then changed its name to Fairgrieve Mouldings back in the mid-’70s, becoming Fairgrieve Composites in 2010 and then changing our name again in 2021 when acquired by Daniel Beaumont to Fairgrieve Compression Moulding. The retention of the Fairgrieve name was somewhat deliberate so as not to lose the history and identity of the business.

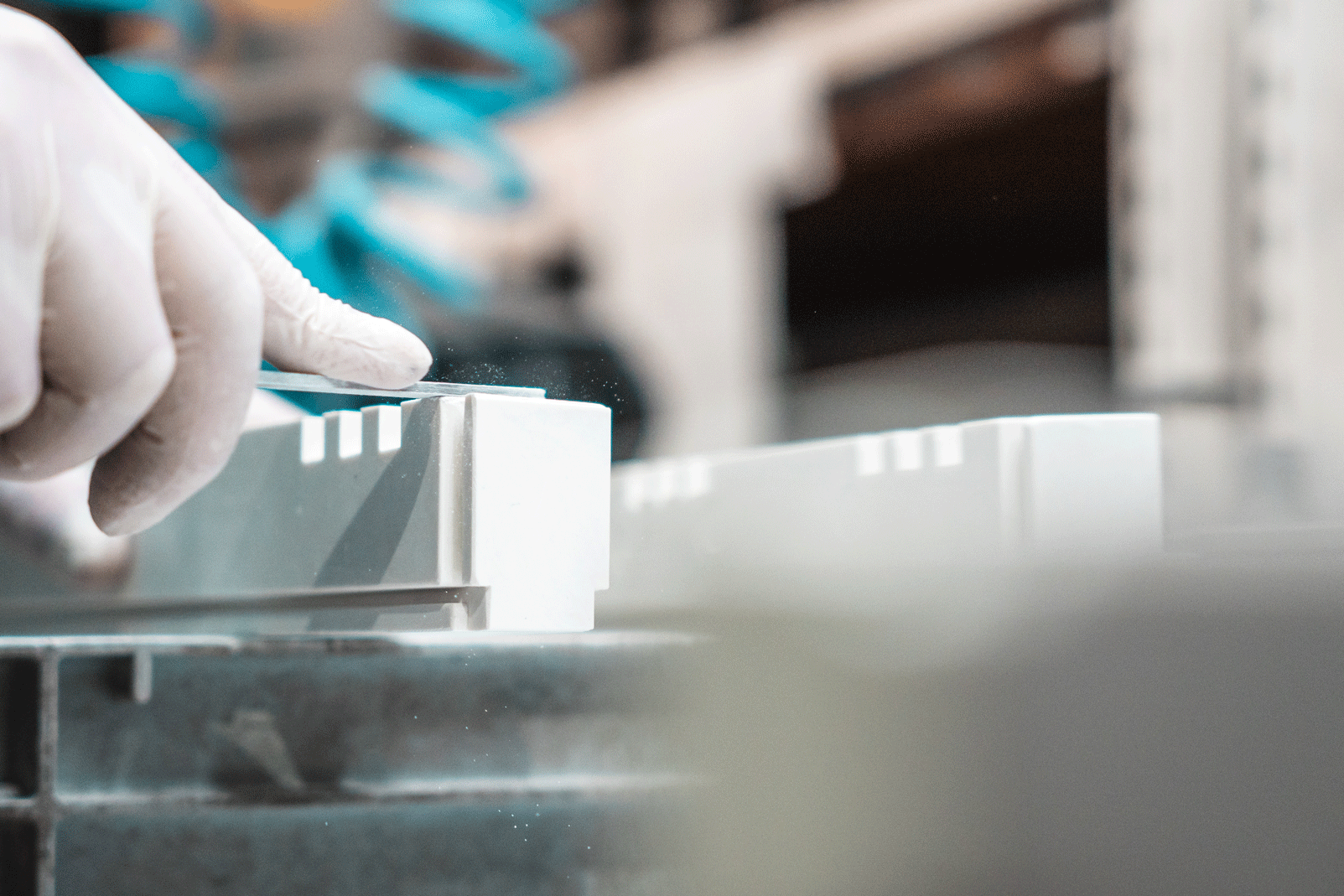

Today, Fairgrieve Compression Moulding specialises in the manufacture of innovative compression moulded parts for a wide variety of industries including mining, construction, electrical distribution, marine, air defence and many more. But as Barry Davidson, the firm’s General Manager, points out, the industry is changing.

“Like so many skilled professions we have seen the compression moulding industry slowly contract where we now compete in a much smaller marketplace,” Davidson says. “We are now the only compression moulding specialists located in the North of England and in total only a dozen or so compression moulders now exist in the UK.”

“Like so many skilled professions we have seen the compression moulding industry slowly contract where we now compete in a much smaller marketplace,” Davidson says. “We are now the only compression moulding specialists located in the North of England and in total only a dozen or so compression moulders now exist in the UK.”

However, the skills Fairgrieve Compression Moulding has to offer are still in demand, and the company’s reputation in the marketplace means it is supported by a loyal customer base.

“I would say that our unique selling point has to be our skilled workforce, many of whom are long-serving employees, in some cases with more than 30 years’ experience,” Davidson tells us. “It takes many years of experience before our operators are fully trained and skilled at manufacturing these bespoke products.”

Those skills are put into action through a vast array of compression moulding presses capable of applying anywhere between 80 tons to 600 tons of pressure, and a temperature range between 100 and 400 degrees Celsius.

“That gives us an arsenal of machines that our competitors simply don’t have,” Davidson says.

Building on a Reputation

That combination of skills, equipment and reputation makes Fairgrieve Compression Moulding a compelling prospect. This is why, in April 2021, the investor Daniel Beaumont decided to make it part of his Group of businesses.

Each company in the Group operates autonomously and is responsible for its own financial performance, however, they all have one thing in common, marketing.

“The Group recently recruited a Group Marketing Manager, Marcus Thrall who has many years of experience in this field,” Davidson says. “He is now helping us all to promote our businesses by defining our market audiences and creating greater awareness of our businesses, products and people.”

Davidson is grabbing this opportunity with both hands. Fairgrieve is over a hundred years old, but despite being a well-established business, many people have not heard of it.

“Being part of a larger group also has its advantages when visiting the different sites and learning how the GMs at those sites have driven improvements,” Davidson tells us.

It also led to a new public face of the company.

“We realised that we would need to invest in a new web page which we did after engaging the services of Arrival Design,” says Davidson, adding that it has already led to increased traffic and sales interest.

Driving Improvement

It is clear from our conversation with Davidson that driving improvement is a topic close to his heart.

“In the two years I have been the GM at Fairgrieve since its acquisition by Daniel Beaumont we have gradually transformed the business from loss maker to profit maker through a programme of continuous improvement activities,” Davidson points out. “The company had previously been a family-owned business and like so many similar situations, a lack of focus and direction meant that the business wasn’t profitable or efficient.”

But while Davidson was quick to identify zones for improvement, like Beaumont he also recognised the company’s potential.

But while Davidson was quick to identify zones for improvement, like Beaumont he also recognised the company’s potential.

“In the past two years this closely knit team I inherited have given everything to this transformation, under my leadership and direction,” Davidson says.

As well as guiding the company, Davidson has also delegated tasks to highly competent staff who had previously not been involved in any decision-making.

“We have seen two key people being promoted in recognition of their efforts and contributions,” Davidson says proudly. “We have thrown everything out of the pram and started again, particularly with pricing, purchasing and planning before moving on to the process (our four P’s if you like).”

Fairgrieve has been implementing a programme of 5S Workplace Organisation, empowering its people, and dramatically transforming the factory with a safer and more efficient process layout that generates greater outputs.

“It is now over two years since we had our last reportable accident,” Davidson says. “Following the transformation, we have received such positive feedback from our employees, customers and suppliers that we have been entered into a National Manufacturing and Engineering Award where we have been nominated as finalists.”

The company has held the ISO 9001 Quality Standard for more than 15 years and is proposing to integrate this with the ISO 14001 Environmental Standard and ISO 45001 for Health & Safety in the workplace.

“Work is already well underway with this project, and we are aiming for independent accreditation by the end of 2023,” Davidson says.

All these efforts are paying off. While Davidson is unable to give details, he confides in us that the company has been contracted by a major player in the air defence sector to manufacture a significant volume of compression moulded anti-aircraft missile tips used by fighter jets in combat. Davidson also tells us that Fairgrieve is currently working on a new development project with a major blue-chip company to produce a compression moulded electrical part for sub-sea applications.

“The specially developed material is from a family of super materials renowned for their conductivity and barrier properties,” Davidson says. “It would appear that Fairgrieve is one of the very few suppliers in the world who can manufacture this part.”

Fairgrieve is continuing its 30-year record of serving the rail travel sector, working with Signal House to supply them with a key part for railway signalling systems used by rail companies all over the world.

What all these projects have in common is that they offer more opportunities for the continuous improvement Davidson is so passionate about.

“At the moment we have a project underway to aid material selection and storage using the lessons learned through our 5S workplace improvements,” Davidson says. “Continuous Improvement is part of Fairgrieve’s DNA these days.”