Abriso Jiffy is a specialist in the extrusion of polyethylene (PE), polypropylene (PP) and polystyrene (PS) into technical foam solutions, profiles, foam and air bubble products, as well as flooring underlay, insulation boards and pipes.

“We are the European market leader in protective packaging and insulation products,” says the Group CEO Jean Baptiste De Ruyck, pointing out the company’s comprehensive, industry-only complete offering is what distinguishes Abriso Jiffy from others.

“With 17 plants spread throughout Europe, we are the only company within our industry that has Europe-wide coverage, serving over 5,400 customers. Our competitors are mostly local or focus on only a limited number of products. The sheer scope, in terms both of products and of geographic coverage, is clearly our USP.”

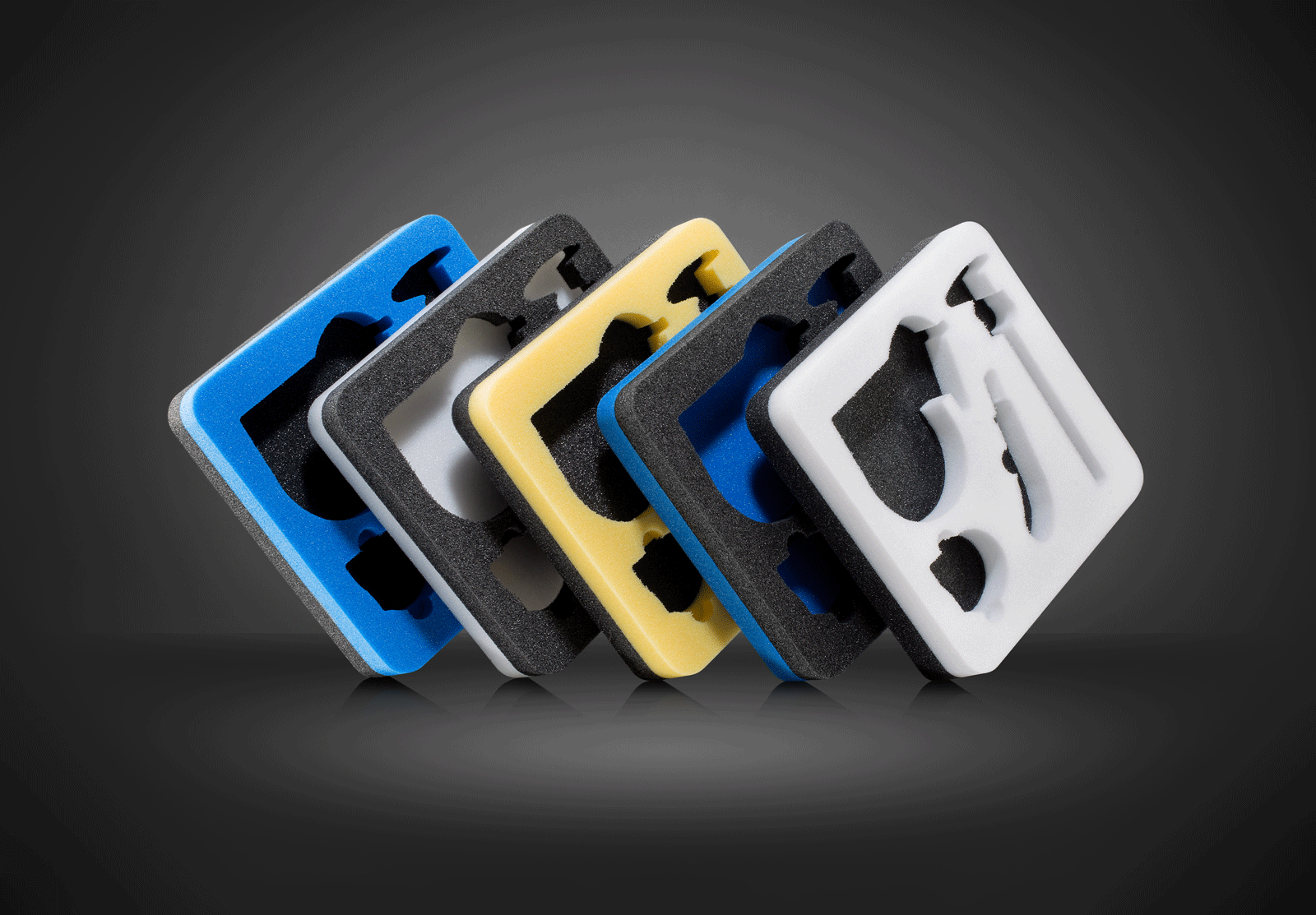

The packaging category includes a full spectrum of products for a wide variety of applications across industries, from foam, bubble and profiles to technical foam solutions and mailers. In the insulation product group, the company offers both contact sound and thermal insulation to protect against sound, heat and cold.

“The protective packaging product range is historically the largest part of the business, accounting for 70% of our turnover. However, in-sulation products are the area that is set to grow most,” he points out.

European business

European business

Before 2019, Abriso was a local business. Then came the acquisition of Jiffy Packaging, doubling the size of the business and significantly increasing the number of production sites.

Abriso Jiffy itself was acquired in mid-2021 by Quva, the investment vehicle of Belgian entrepreneur Pascal Vanhalst, who pushed for further expansion with a view to making Abriso Jiffy a truly European player. Since then, several more acquisitions have followed.

“In 2019, we were a small business turning over 100 million euro. At the end of 2022, the figure was over 300 million. We have evolved from a local business to a European leader in just over four years,” says Mr De Ruyck, who himself joined the company at the onset of its expansion, in 2019.

After business consolidation comes business integration, a challenge Mr Ruyck has focused on over the last 18 months.

“We are trying to bring together all the individual companies, previously competitors, to work efficiently as a group. This means a lot of change management, many organisational changes, building a professional structure, creating a joint culture and a joint market approach. Implementing a more unified commercial organisation, a more effective organism, has been the task for 2023.”

He affirms that the speed and success of this integration have been a great achievement. “We have succeeded in making people work together, changing the local to a European mindset, bringing the individual parts together into a strong, robust unit. Change is obviously very hard for many, but when it all works, it is a great satisfaction. After all this effort, everything starts working together and the magic happens.”

Sustainable approach

Going forward, sustainability will remain a big topic, and Mr De Ruyck explains that the company first looks at aspects it can control – the type of products launched onto the market. The second challenge is to produce them in the most sustainable way.

“We invest a lot in R&D to come up with sustainable solutions for our clients. All products that we place on the market are recyclable – we offer 100% recyclable foam, 100% recyclable bubble as well as 100% recyclable polylam and plank.”

In terms of how the products are actually made, a lot of emphasis is put on increasing the amount of recycled content, he says. “The aim is to make recyclable products based on recycled content. We are trying to find a sustainable alternative in every product category.

A good example is our Ocean Green label which bundles products which are based on 100% recycled content such as Ocean Green bubble, profiles and technical foams.

The company is also investing in its own sustainable operations. Abriso Jiffy has no waste as everything is reused. The scrap from the production process is used to create ‘granulates’ which are then used to make whole new bubbles, foams, profiles and countless other products. The company is also finding ways of collecting more scrap from its customers/convertors in order to establish a closed loop for its products.

When reflecting on current market developments Mr De Ruyck points out that over the last 18 months, the demand for sustainable products has further accelerated. “Sometimes this is a challenge as there are technological implications, requiring more research and development, to enable increased use of recycled content. This is something we work on with machine manufacturers. Another trend we need to reflect in our business is digitisation. To this end, we are investing in automation as well as in new, energy-efficient technologies.”

Steady consolidation

Steady consolidation

With its diversified product portfolio designed for a range of industries, Abriso Jiffy shows sound resilience against market developments. “When we look back over the last two and a half years, we were not that exposed to the sectors that have been impacted by the pandemic and related disruptions the most.”

“We were also benefiting from the incremental amount of e-commerce. Now we see the building sector under huge pressure due to increased prices but the automotive is picking up again. Our diversified exposure clearly plays into our hands. Also, as we are a local, European business, we are ‘China-proof’. We have had very good relationships with our suppliers and have benefited from our long-term partnerships, based on trust.”

As a strong, well-established group, future prospects are good, says Mr De Ruyck. “Our owner, with its extensive manufacturing experience, has a long-term view for the business, and is ready to further invest in people, in technology, in R&D, and in digitisation.

Further acquisitions are always on the agenda, but it is important to make sure that these are absorbed in a controlled manner.”

As the provider of the most diverse and complete offering on the market, Abriso Jiffy is clearly set to face the challenges and opportunities of the future.