The Netherlands-headquartered Veco is a world-leading manufacturer of micro-precision parts using electroforming technology. Unlike traditional methods such as chemical etching, stamping, deep drawing or laser, electroforming can deliver mass volume at superior accuracy down to 1 micron with extreme design complexity.

Veco is the leading company in the electroforming industry, operating the largest production facility in the world. The company specialises in Advanced Lithographic Electroforming, primarily using materials like nickel but also palladium nickel or copper to meet specific requirements. Veco is also the first in the industry to apply advanced Laser Direct Imaging technology in high precision metal parts manufacturing.

From its two production facilities in the Netherlands and India, the company serves the world’s most innovative, high-tech companies in a diverse range of industries that demand high quality and precision, from medical and automotive to food and beverage to aerospace.

Ready to seize new opportunities

Ready to seize new opportunities

We spoke to company General Manager Mischa Baert, who joined the company a year and a half ago, following a long career in the aerospace industry, in order to navigate the business in the rapidly changing market conditions and steer it towards novel applications and new markets.

He says: “It is exciting to lead the company in the times of great changes in the marketplace. But I’m not doing it alone – we are a relatively new leadership team, supported by 170 enthusiastic and proud employees; everybody is ready to move the company forward and capitalise on emerging opportunities.”

He explains that Veco operates in a niche business. “While the electroforming process is not unique, and there are other companies that use the electroforming method, we stand out with our in-house design and knowledge base and the ability to support clients in developing tailored solutions.”

“We are a well-established company in the metal parts business and have a strong track record in digital printing, medical devices, filtration, measure and control devices. Now we are starting to make strides into new sectors, like the semiconductor industry, where demand for micrometre-level precision has opened up opportunities for us to supply components that require exceptional accuracy and material durability. These are areas in which we excel.”

“New opportunities also emerge as a result of the growing sustainability trend that is reshaping industries. We are exploring our role in hydrogen production – for example, our precision components can enhance the efficiency of hydrogen production.”

He further affirms that customers increasingly seek smaller, more accurate components, pushing the company to refine its processes and adopt innovative materials. The ability to tailor solutions to specific needs – whether that involves flexibility, durability, or unique characteristics – has become a crucial aspect of Veco’s offerings.

Technical challenges, such as achieving optimal aspect ratios for ultra-thin yet precise products, have prompted Veco to invest in technological advancements, adjusting processes to support the higher accuracy demanded by the market.

Working in partnerships

To sustain the highest levels of quality, solid partnerships with suppliers are crucial. The company has a global supply chain and Baert reflects that it is not location that is the most important criterion when choosing suppliers, but their quality and expertise.

For example, the company relies on the experience of MacDermid Alpha, a global material and chemicals supplier. “MacDermid Alpha know their way around not only our base materials, but also the support materials and chemicals we need in our processes.”

“They really are a key supplier for us, a reliable partner to supply our current business and making sure we can get our quality and delivery right, maintaining our production standards but also in developing future solutions that would need to be adapted to regulatory changes.”

“Another important supplier is VIRO, a Dutch family-owned international engineering firm and development partner for the industry. VIRO is specialized in custom-built process/production equipment and collaborates with us to develop tailored solutions for our highly specialized production needs. The added benefit of VIRO being a local company is of course welcome, as it enables a lot of interactions and iterations to make sure that together we come up with the optimal solution that we’re looking for.”

Sustained growth and leadership

Sustained growth and leadership

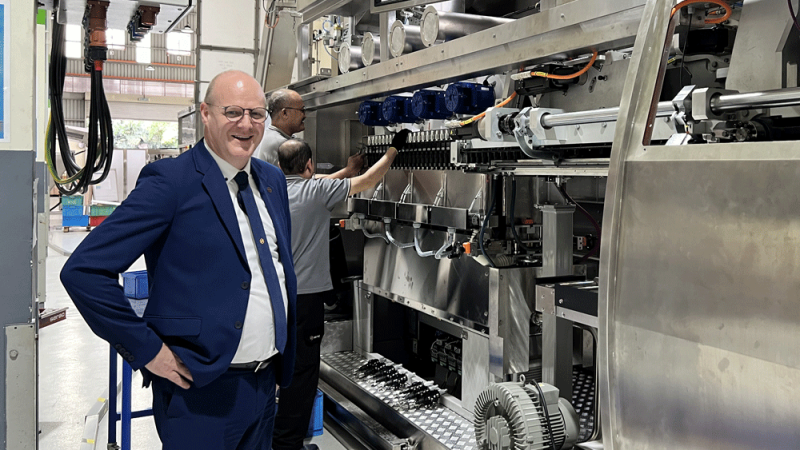

Today, the company employs some 175 people in its Dutch plant and just over 100 at its Indian facility. “Over the last few years, we have invested both in new technologies and in facility expansion. This has partly been to secure redundancy so that we can support the growth but also to enhance our technology base, increasing the level of automation,” says Baert.

“Automation plays a key role in addressing the challenges posed by a tight labour market in the Netherlands, reducing dependency on manual labour while improving production efficiency and consistency.”

“We are also investing in new developments, to be ready for the next level of precision and application of new materials. So an investment is being made in both hardware and in enhancing our internal knowledge base – conducting experiments and securing patents to stay ahead in its field.”

In concluding, Baert affirms that Veco is well-positioned to seize opportunities in high-growth sectors like semiconductors and hydrogen production. The support of its parent company, IDEX Corporation, further strengthens its prospects.

With access to IDEX’s financial stability and operational expertise, Veco is well equipped to execute its ambitious plans, which potentially include geographic expansion to locations close to the customer, should the market demand for hydrogen production grow significantly.

“My plan, discussed and agreed with my team, is to double the size of the business within the next five years. This is ambitious but not out of reach, given our track record and developments in the market. By aligning with industry trends, investing in advanced technologies, and emphasizing sustainability, we are ready to progress toward sustained growth and leadership in our markets.”