Damen Naval is the largest division of the Damen Shipyards Group and covers all the naval activities of the Group. With an impressive history going back to 1875, when the Royal Schelde Yard was founded in Vlissingen, Damen Naval is today the only naval original equipment manufacturer (OEM) in the Netherlands.

Managing Director Roland Briene explains that while the company was active over the years across a variety of sectors, and employed some 5,000 in its heyday, becoming a member of the global Damen Shipyards Group in 2000 sharpened its focus on shipbuilding services alone.

He affirms that the company is getting ready for the big celebration next year. “Reaching 150 years of being a privately owned naval shipbuilder, still alive and kicking, is something to be proud of. This history is part of our heritage, but we are also looking into the future, embracing new opportunities.”

Trusted partner

Trusted partner

The company has a long tradition of serving the Royal Netherlands Navy and this relationship is set to continue with the contract to build the RNLN’s new Combat Support Ship and the new Anti-Submarine Warfare Frigates (ASWF) for both the Netherlands and Belgium.

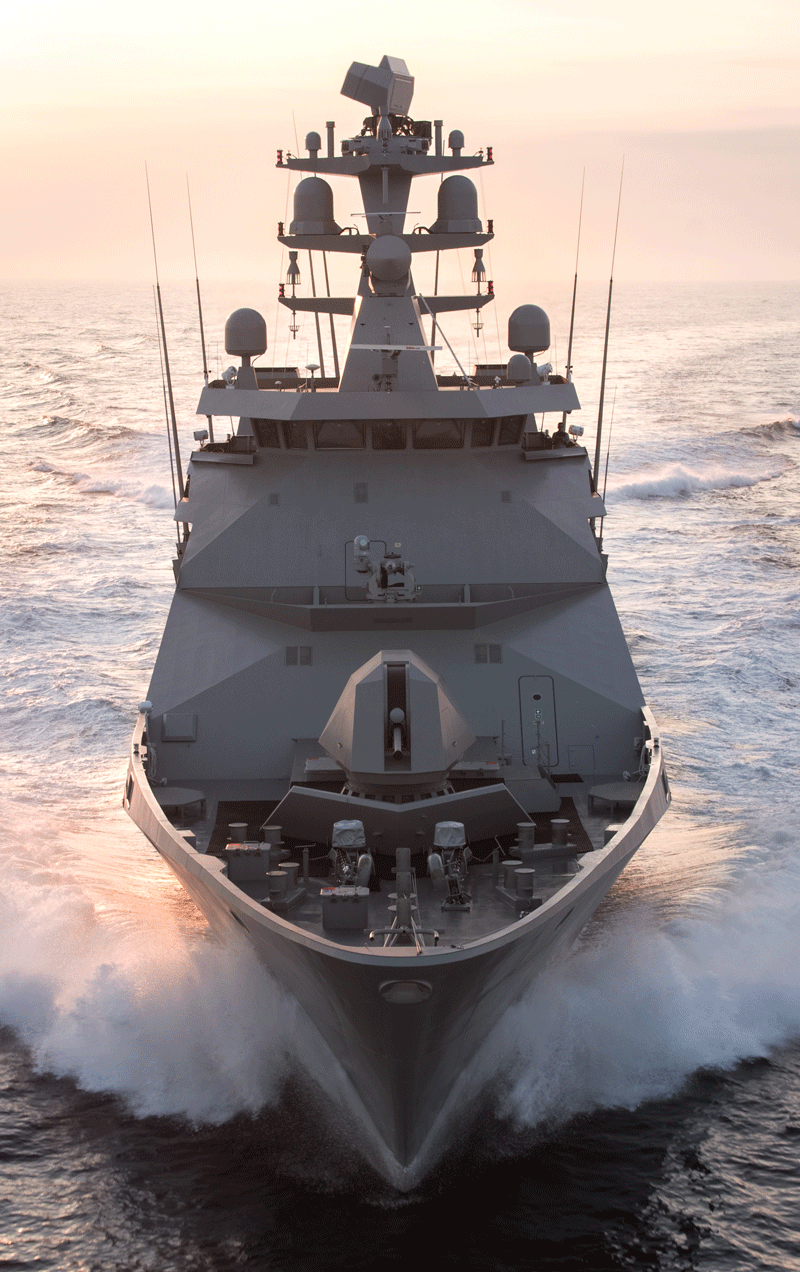

Damen Naval was also selected for the design and build of the German Navy’s F126 frigates. This contract, awarded to Damen Naval in June 2020, represents a significant upgrade to the German navy. At 166 meters in length and with a displacement of up to 10,000 tonnes, these frigates are set to be the largest in the fleet. Designed as versatile multi-mission platforms, the F126 frigates can operate globally across diverse conditions, from tropical climates to polar regions.

Briene points out that Damen Naval’s order book is at a record high. “Important new contracts were signed before the pandemic as a result of the planned investment by the Dutch and German Navies, and the current geopolitical situation means that demand for our vessels is increasing.”

“In total, we are now building eight frigates, four for the German Navy and four for the Royal Netherlands Navy- and Belgian Navy,” he says, adding that the German Navy chose to exercise its option for two additional frigates so the company now has a total of 10 frigates under contract, in addition to other projects ongoing for the Royal Netherlands Navy and other parties.

In a new shape

These major contracts, which began to be implemented right in the middle of a pandemic, brought significant changes to Damen Naval. The company had to increase staff numbers from 400 to 1,200 and implement a number of new IT systems. Needless to say, successfully integrating all these new engineers, and making sure that all programmes and systems were effectively in place, was a significant challenge in a ‘locked down’ world but one that was handled successfully.

“We managed to find new people, not only from the Netherlands, but also from Spain, Portugal, France and other countries who relocated to work with us. Ensuring that these new people did not feel isolated was key,” affirms Briene. “Ever since then, the wellbeing of our people – our core asset – has become one of management’s priorities.”

Following the Russian invasion of Ukraine, it was clear that there is more to come, says Briene, and more changes would be needed. “That was the moment where, in 2022, we decided to restructure the company and re-define our strategy. In 2023, a completely new structure was implemented with new systems and procedures, setting us up for the large contracts that were to come, making Damen Naval ready for the future.”

Clear differentiators

Clear differentiators

With its proven track record, Damen Naval stands out with several strengths. Supply chain management is one of them. Some 150 to 200 suppliers and co-makers are needed for a large frigate, so coordinating the work requires skilled hands. “As the national OEM for naval shipbuilding, we work with many subcontractors, suppliers and co-makers and are experienced in integrating a lot of such systems into a single system,” explains Briene.

“For example, within a single contract with a customer, we integrate all the weapon systems, all the sensors, and other equipment into our own systems to produce a functioning warship that can fight and win at sea. Basically, we engineer and build a ship by integrating a lot of components with co-makers. That is quite a special capability.”

“The other differentiator, from the bigger perspective within the Damen Shipyards Group, is our capability to provide a full range of ships to navies from a small patrol craft up to fully fledged frigates.”

The company can also leverage the advantage of Damen Shipyards Group’s global sales organization. “Where in the world there is water, Damen is there also. This geographical spread has boosted our exports and helped us to sign contracts with clients in Indonesia, Morocco and quite recently, Colombia, where we will work closely with a local shipyard to build a frigate for the Colombian Navy.”

Fit for the future

To meet all this emerging demand, utilisation of capacities has to be carefully considered while making sure that the demanding requirements of the company’s long-standing customer, the Royal Netherlands Navy, are duly met, says Briene.

“We are now looking into the 30’s horizon for new contracts. We have to carefully assess the efficiency of our yards to make sure that we are ready to produce what our clients need in order to prepare for the worst – that’s what naval shipbuilding is about,” he says.

In concluding, he reflects that over the 150 years of its existence, the company has gone through major changes and has survived in robust shape – a remarkable achievement. “The flexibility and adaptability to new developments has been an integral part of Damen Naval and will continue. With the new efficient business structure, we are fit for the future.”