American Battery Factory is a two-year-old company, but the idea behind it has been around for half a decade. Its origins lie with Lion Energy, a leading manufacturer of safe, silent, and eco-friendly power solutions for everyday needs, which had been working out of Utah for ten years. Business was good, but the people who would become American Battery Factory’s founders saw a gap in the market – a gap that urgently needed to be filled.

“The Lion Energy team realised that the demand for long-term battery storage was becoming more important, but was not being met,” says John Kem, President of American Battery Factory. “At the same time, we recognised that US and European supply chains were not yet a part of the battery storage world. That was the genesis of American Battery Factory. At ABF, our real purpose is to bring scale into the domestic US battery manufacturing skillset, starting off with lithium iron phosphate battery cells that offer the safest and most secure clean energy solutions possible today.”

The need for a company to fulfil that purpose is obvious to everyone familiar with the sector. Over the last ten years the market has been dominated by Chinese manufacturers, and US and European counterparts have struggled to match the scale of those operations. However, Kem is adamant that western manufacturing has something to offer.

“There are some unique, small production facilities in the US and Europe, but the benefit here is we can use US expertise in machine learning and technological and IT solutions to take those operations to the next level. That is what we are trying to do, bringing our ingenuity to the sector.”

Building a New Supply Chain

Building a New Supply Chain

Kem and the rest of the ABF leadership team recognise that American Battery Factory is competing in a sector where its competitors have a head start. Battery manufacturing demands an array of highly sought-after materials that must be sourced continuously, and reliably.

For the power storage that American Battery Factory makes, it requires 16 primary materials, including lithium iron phosphate (LFP), electrolytes, special foils/fabrics, and ceramics.

“All of the materials are essential, and trying to build a US and North American supply chain for those is a huge endeavour,” Kem says. “In the long run, we want to build these not just in the US but also anywhere where large-scale battery demand is important. That is the driver behind what we are doing, and we are uniquely positioned to deliver it.”

American Battery Factory has put itself ahead of the curve in creating that supply chain alongside its very high-level manufacturing capabilities.

“Trying to source all those materials through what is currently a nascent domestic supply chain is a challenge,” Kem says. “A few of those materials are hard to come by. There is no scale level LFP supplier in the US. We are excited to work with the lithium suppliers the US does have, but they do not have the scale quantities we need yet. For example, we need 7,000 tons a year of LFP for our initial production line. Nobody is doing it at high quality and high scale at this moment. So, we have to pursue and draw from three or four different sources. It is an interesting dance, mitigating all these things to create a safe, reliable, high-quality supply at a reasonable price.

You cannot pay three times more than China does and be competitive.”

But American Battery Factory is working to establish itself as the foundation of an entire industry, and that means bringing the companies it works with along with it.

That includes partners such as Honeywell, LEAD, and others, who American Battery Factory has worked alongside to bring about better analytics and waste reduction.

“We have a 1,500-foot-long factory,” Kem points out. “If there is a fault at the beginning of the production line, you want to find that out early.”

Being able to bring this knowledge to bear is what sets American Battery Factory apart, as well as its ongoing commitment to continuous improvement.

Building a Smarter Grid

Building a Smarter Grid

But alongside the structures it is building, in terms of supply chains and manufacturing facilities, it all comes down to the product. American Battery Factory’s actual batteries are high-quality, long-lasting, and ready to meet the urgent needs of the energy sector.

“They are so much longer lasting,” Kem says. “A typical EV battery will have six-to-eight years of life. With prismatic folding at scale and other processes and material improvements, we can make batteries that reach 10,000 cycles. In real terms that means 15-to-20 years of life.”

Through its partnerships with cutting-edge companies, American Battery Factory’s batteries can support home battery storage, as well as power storage for data centres and even military applications.

“The challenge and the needs are to be dynamic,” Kem insists. “That reality is evident if you look at the US and the electrification that needs to happen here in the next five to eight years. Particularly, the energy storage demand for AI computing is a major factor. It makes up 2.5% of US energy consumption already, and in five years we can expect that to reach 12.5%. The US grid cannot grow fast enough to provide that alone.”

As those needs increase, from AI computing and other sources, the only solution is to create a smarter energy grid for homes and businesses alike.

“If we had between four and twelve hours of energy storage in every home, it would mean that in a disaster there was less need to get emergency power to people,” Kem says. “And in a summer or winter period of high risk of demand overloading supply, a smart grid could potentially turn my power off for two hours and I wouldn’t even notice. It is the only way to meet the demand we have incoming in the next few years. To build that smarter grid, we need ABF’s LFP battery cells for safe, reliable energy storage. That is why being able to produce those inside the US, with US workers at scale, is important.”

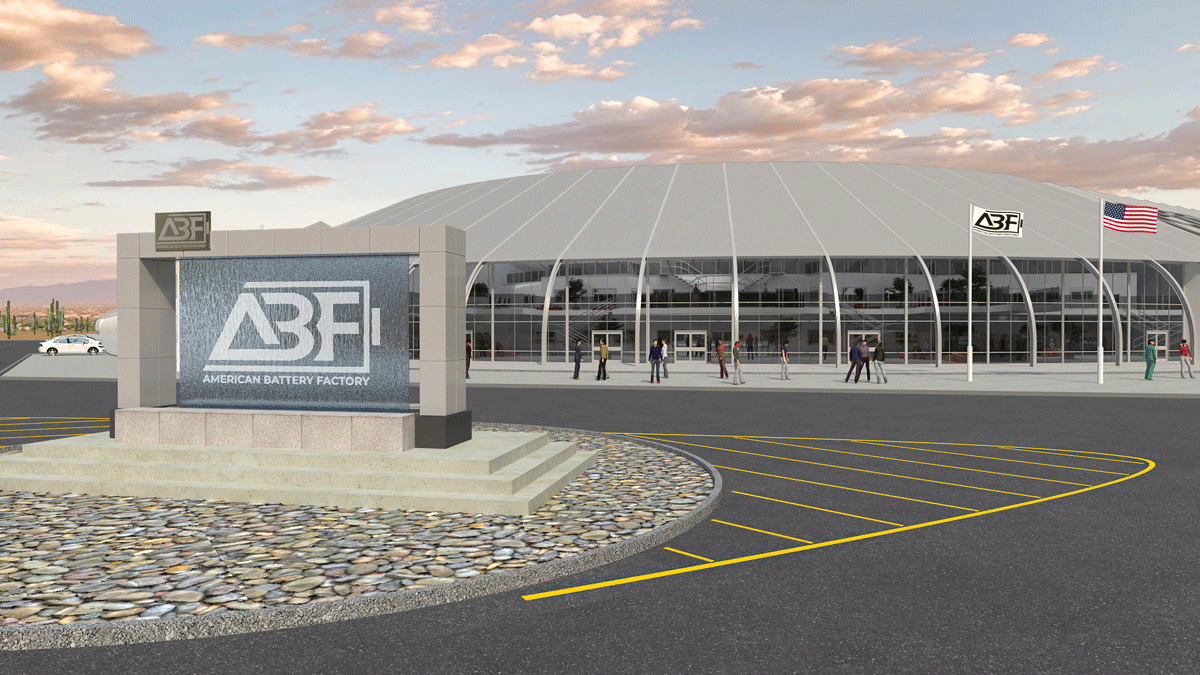

To support that new grid, American Battery Factory is currently constructing an initial 4 Gigawatt-hour factory at its 70-acre site in Tucson, Arizona. It will be in production in less than two years, with more and larger factories set to follow.

But as well as the technology and the materials, that factory will also need people.

“It is important that people realise this is hard work that takes committed people, but it will transform smart manufacturing in the US,” Kem tells us. “The initial factory will employ about people, and they will not be doing repetitive button-hitting work; it is high-end, cutting-edge computerised manufacturing. The closest equivalent is high-end pharmaceutical work. If we want batteries with a 15-to-20-year lifespan, we need a workforce committed to quality and innovation making them.”