Hahn Plastics was established in Germany in 1993. At a time when sustainability was still considered a relatively niche issue, the company was already making a name for itself in plastics recycling. Over the last 30 years, it has established footprints in not only Germany, but the UK, France, Italy, Iberia, and Canada.

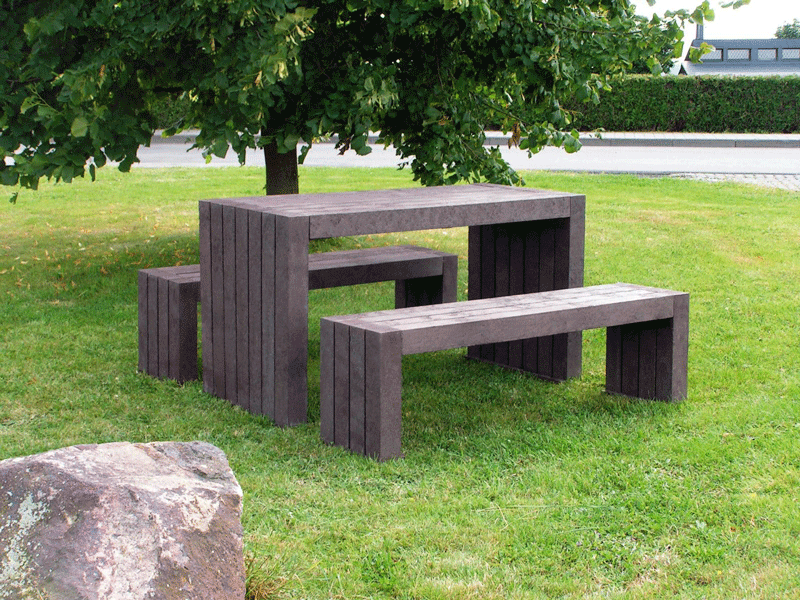

Hahn manufactures a 100% recycled material, hanit®, which it offers as a sustainable alternative to wood and concrete. Today the company offers a range of over 2,000 hanit® products, including bespoke designs developed with customers to meet their needs.

“We are the leading brand for taking common consumer waste plastics that typically could not be recycled and transforming them into high-quality, long-lasting products,” says Dave Watson, Managing Director of Hahn Plastics in the UK. “We aim to use waste streams local to our markets to satisfy customer needs and lower our impact on the environment.”

One Person’s Trash…

One Person’s Trash…

The products that Hahn Plastics converts from waste go into a variety of markets. This diversified spread of customers has shown to be an asset to Hahn Plastics’ growth. Its products include tongue and groove products for the equestrian market, which look like standard wooden tongue and groove boards but are less appealing to horses looking to chew on them.

“When you are mucking out a stable you can simply hose our products down because there is no absorption,” Watson points out. “It is so much more superior to the wood equivalent.”

Hahn Plastics also sells landscaping or fencing products, products that have to be regularly renewed when made of other materials, but which with Hahn’s materials can last up to 120 years.

“We provide anything from truck parks where recycled plastic is incredibly good under compression, to replacing a variety of permeable concrete grids with plastic that tend to be lighter and able to be installed by one person,” Watson says.

Its products have also been used in large infrastructure projects for customers such as Network Rail or the Highways Agency. It has manufactured BBA-approved retaining walls for the sides of motorways and railway tracks, offering a more resilient and versatile alternative to concrete with a lower carbon footprint.

“Our products in the UK are manufactured using renewable energy, so our carbon footprint is better than wood or concrete equivalents over the full lifecycle of the product,” Watson tells us. “We are also looking at future applications for our street furniture range. We would love to take low-grade plastic waste from cities and convert it into park furniture around city centres. It is a great opportunity for the circular economy.”

When these products do reach their end-of-life, they can be simply returned to their manufacturer, who will grind them down and reuse the materials elsewhere.

It is an important point to make when many customers are reluctant to use plastic for environmental reasons.

“We believe that our range of recycled plastic products provides an effective solution to the environmental harm that virgin plastic can cause,” Watson tells us. “We are intercepting plastic waste and diverting it from oceans and landfills to turn it into genuinely beneficial products. Our use of un-reusable post-consumer plastic waste is a serious differential for us, letting us preserve natural resources and reduce the damage plastics can cause.”

Hahn Plastics is passionate about preserving natural resources. Surprisingly, it is sourcing the waste it uses at the right price points that can be its biggest challenge.

…Another Person’s Treasure

Hahn Plastics has grown over the years to the point where it has the scale to serve large-scale projects, and the materials it produces are the best-performing and most suitable materials on the market.

But while the German branches of the company benefit from a centralised recycling infrastructure, Hahn Plastics in the UK faces real challenges when it comes to sourcing the kind of waste that it uses for raw materials.

“Access to low-quality post-consumer plastic waste has been one of our biggest challenges,” Watson says. “We have seen volatile prices for feedstock and recycled film in the feed market, so anything other than clean post-industrial film can be a challenge to recover and use.”

The difficulty in finding the materials Hahn Plastics needs does not come out of the scarcity or value of those materials.

The difficulty in finding the materials Hahn Plastics needs does not come out of the scarcity or value of those materials.

“They cannot be reused by anyone else because they are too low grade to be effective,” Waston says. “But the processes we have developed can prevent those products from going to landfill or being burned.”

In Germany, Hahn Plastics has access to a centrally run established recycling scheme, but without that in place, the UK arm of the business has established a robust raw materials supply chain, developed, and grown from the ground up.

“It is primarily drawn from the UK, but unfortunately not all of it,” Watson says. “Having that supply chain in place is helping us to grow sustainably while enhancing the quality and consistency of the products we supply to the market.”

But waste plastic is not the only resource Hahn Plastics is keen to seek out. As the company grows, it is also on the lookout for people who can help it realise its vision. It attracts and retains the talent that it needs through the company’s core values. Those values include Caring; referring to how the firm treats its customers and employees, Sustainability; in every way and beyond the product we make, and Innovation.

“People are starting to realise the benefits of sustainability,” Watson says. “We are looking for people to join us who have that innovative flare. We are a growing company but not a large corporation, so we can be agile to meet the market needs, and that is something we look for and encourage in our team members.”

Hahn Plastics works to help its employees be the best people they can be while delivering on the expectations of customers and stakeholders alike.

“We aim to create value for our customers while providing clear communication and timely updates in the right place with the right language and the right medium,” Watson says.

“We look for people that we can develop who can build relationships with stakeholders and follow our core values. We want to stay versatile, and ready to meet all potential applications – even ones we have not heard of yet, to help our customers achieve Net Zero.”