Kuehne Chemical Company is a 100-year-old family business in the commodity chemicals market, specialising in making bleach. But its work is about interpersonal chemistry as much as any other kind.

“We are a people-centric company,” says Zach Kuehne. “Where a lot of companies in the commodity chemical businesses focus on being competitive through low costs, we invest in our people to create a strong environment and community within the company. We talk about the three dimensions of happiness in our Human Resources department – physical well-being, emotional health, and financial health. Given how much time our staff spend at the company, we feel we have a duty to help across all three dimensions.”

That does not mean Kuehne does not compete on the low-cost side of the market, 85% of its business is in that sector, but it is always backed up by excellent customer service and a reliable supply chain.

“Our strategy is to stay somewhat regional and local in the Northeastern and Mid-Atlantic regions,” Kuehne tells us. “When one of our facilities needs to experience an outage, we can seamlessly bring products in from other facilities. That surety of supply is critical to our customers, especially in sectors such as the drinking water industry.”

Kuehne’s facilities not only have overlapping spheres of influence but also the flexibility to switch their output between two different bleach production methods, acting as a double insurance against difficulties in the supply chain.

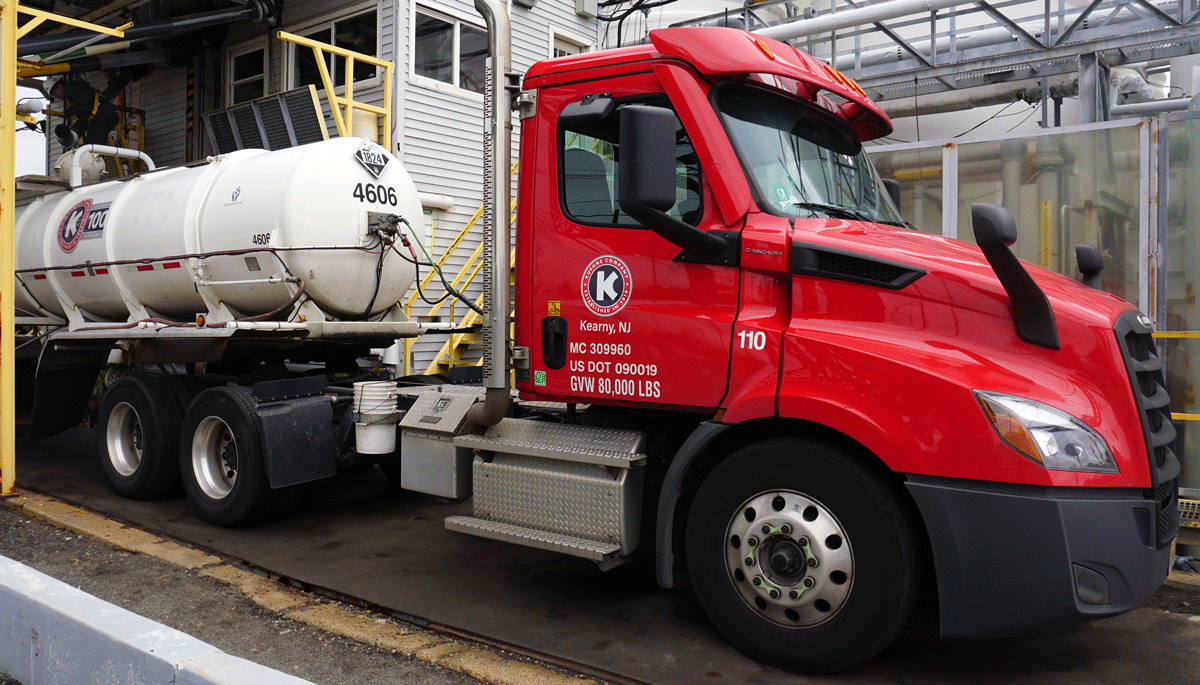

“We also own our own transportation business, so we can schedule and deliver loads as and when we need to,” Kuehne says. “It means customers can call us on phone lines that are manned 24 hours a day, seven days a week and we can respond quickly to their needs.”

Of course, an occupational hazard of any low-cost sector is that customers will come and go depending on the vagaries of the market.

“Due to the exceptional quality of our product and our unparalleled customer service, customers typically return, often feeling a sense of relief when they do,” Kuehne says.

A Family Recipe

A Family Recipe

Competing on cost is an occupational hazard, and competing on service gives Kuehne the edge it needs, but neither selling point is worth anything without the quality of the product to back it up. Fortunately, Kuehne Chemical Company has no concerns on that front.

“We have a propriety process for our own concentrated bleach,” Kuehne tells us. “My father was an engineer, he designed, tested, and built out a process to make a more concentrated bleach. That is a big deal in today’s industry, especially with the strain on transportation. We can provide bleach at a concentration of 22% by volume, compared to 15% for most bleach.”

The higher the concentration of bleach, the less you need to transport. This provides several environmental benefits, such as reduced traffic due to fewer required trucks, resulting in a significant reduction in CO2 emissions. However, there are reasons why not everybody adopts this approach.

It comes down to salt. “When the available chlorine level reaches 22%, salt begins to precipitate out of the solution, carrying impurities that would otherwise cause the bleach to degrade faster. The higher the concentration, the more salt precipitates out. It then re-forms into crystals,” Kuehne explains. “Our proprietary process enables us to recover and reuse this excess salt, contributing to a more sustainable production process. As of now, we can produce bleach at concentrations of up to 30% by volume, while recovering a significant percentage of the salt we use. This results in a purer form of bleach that is also more stable. We are continuously making adjustments and improvements, aiming to produce bleach with even higher percentages of available chlorine, further enhancing the sustainability of our production process.”

That the method was devised by Zach Kuehne’s father tells you everything you need to know about Kuehne Chemical Company, which at heart is a family business.

“My grandfather founded the business out of his basement in Jersey City. He was making bleach in a bathtub essentially, which he sold as local laundry detergent,” Kuehne says. “My dad was an MIT-educated engineer who was instrumental in building up the business. I grew up in North Carolina and came into the business later in life after acquiring a business degree.”

A Family Business

A Family Business

Zach Kuehne’s journey into the company has been an interesting one after growing up away from the family firm’s operations. He first became involved in the company’s operations fifteen years after his father passed away.

During the fifteen years before joining the company there was not a Kuehne family member involved in the day-to-day operations,” Kuehne says. “Operating a company from a distance offers a unique perspective, allowing for a broader strategic focus and a bird’s-eye view of the business landscape. However, it also means being removed from the intricacies and nuances of day-to-day operations. It is a shift from overseeing from a distance to being intricately woven into the fabric of daily operations, requiring a different set of skills and a heightened sense of accountability. This hands-on approach demands a keen awareness of the immediate challenges and nimble responsiveness to changing circumstances.”

Indeed, it is precisely the family nature of the business that has driven its people-centric approach.

The importance of people to Kuehne Chemical Company, and the importance of Kuehne Chemical Company to its people, is never far from Kuehne’s mind.

“It has been an emphasis of mine since I became president,” he says. “We have been building an HR team that invests in people. That has always been a focus. For 100 years we have said that people are our greatest asset. The machines do not run themselves.”

This is about more than money and training programmes. Every year Kuehne offers its staff Christmas parties, laser tag and paintball tournaments, and golfing events so staff can get to know each other out of work.

“We also looked at pay rates. Drivers are extremely in demand, so we created a three-tier system with apprentices, journeymen, and master drivers,” Kuehne says. “We have revamped our performance review process over the last couple of years, building a culture of continuous improvement across the entire business.”

That improvement is set to keep going for the next 100 years. Kuehne tells us of plans to invest in the company’s facilities, and he has established a five-year strategic vision that includes a standard template for each of its facilities. He is also looking at new technologies such as hydrogen capture, which will help build the business, but also ensure it is having a positive environmental impact.

As Kuehne says, “If I could summarise our future, we are focusing on what we can control. We are investing in facilities, investing in people, and investing in the environment they work in.”