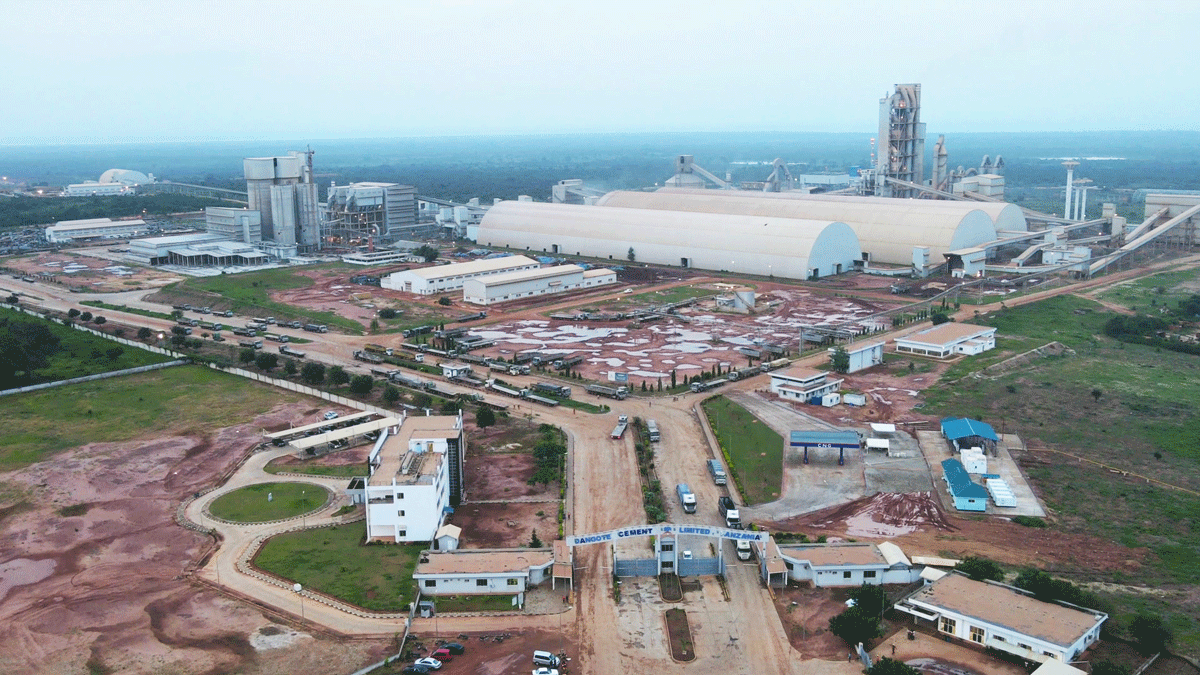

Dangote Cement Tanzania is the largest cement plant in East Africa in terms of capacity, situated in the southern part of Tanzania. As a fully integrated plant, Dangote Cement Tanzania is unique in the sector, connected to the market through road connections and strong partnerships with the local Mtwara Port.

However, despite those strong connections, Dangote Cement Tanzania is still positioned further from its primary markets than is ideal.

“Dangote has to have presence and visibility in the market,” says Dr Ibrahim Lawal, Head of Transport for the plant. “Our prime market is 560 kilometres away from the plant, which means we need a top-notch logistics solution to meet the demands of the market.”

From its position in Tanzania, Dangote Cement Tanzania is able to export to the Indian Ocean Islands, Zanzibar, coastal southern Africa, and the ports of Beira in Mozambique. All in all, the firm supplies seven African countries including Mozambique, Rwanda, Uganda, Burundi, DR Congo, Comoros, and Malawi by both road and sea. To do this Dangote employs solutions including its own transit terminals, truck-to-truck shipping, and its own fleet of 650 trucks.

“We put those trucks to optimal use to ensure we meet our customers’ expectations and create brand visibility for our product across Tanzania and wherever we export to,” Lawal says. “Our fleet handles a return model of logistics, transporting raw materials for cement production as well as distribution, door-to-door delivery, including just-in-time logistics.”

This logistics fleet also reflects Dangote Cement Tanzania’s commitment to decarbonization, with 400 out of the firm’s 650 vehicles running on dual fuel using Compressed Natural Gas (CNG) and Diesel

“It has a huge cost-savings and a key sustainability initiative. We are building a fleet that speaks to the future of the industry,” Lawal says.

A Name to Rely On

A Name to Rely On

Dangote Cement Tanzania’s carefully optimised distribution network is a sign of the unique quality associated with its brand.

“Many of our customers have a flexible distribution requirement, so if you want us to deliver door-to-door we will do that,” Lawal explains. “Whatever their situation, we help our customers choose a model of transport that will allow them to be competitive. Sometimes we will go truck-to-truck, meeting our customers halfway allowing them to alleviate their transport costs. We can also help with truck-to-rail transport to ensure we meet the customers’ expectations.”

The flexibility of Dangote Cement Tanzania’s delivery models means it has a transport niche that grants it a level of uniqueness that attracts customers. “We definitely have a solution to their problems,” Lawal says, simply.

That reputation is hard won, however. Tanzania, like many sub-Saharan African countries, faces challenges around infrastructure, including road and rail, including gaps in the interchange between different infrastructure networks or transport modes.

“At the port of Mtwara we used to have a great deal of difficulty with vessels coming into port,” Lawal recalls. “We resolved that through intensive discussions and engagement with all the stakeholders, including ship owners, cement customers, government agencies and port bureaucracy. We engaged with top government officials to ensure that there were no bottlenecks at the port.”

Today, Dangote Cement Tanzania has 24-hour a-day, seven-day-a-week operations at Mtwara Port and consistently ships between 20,000 and 24,000 tons of cargo a month, with a warehouse dedicated to port operations.

“We have been able to adapt to and create flexible solutions that meet the realities we face,” Lawal says proudly.

A Local Operation

While Dangote Cement Tanzania has built its reputation on a well-optimised logistics and distribution network that stretches across several countries, Lawal is adamant that it is ultimately a local company supporting the local community.

“Our production and manufacturing are all 100% fuelled by local content,” Lawal says. “We do not import anything to support what we are doing. From a social angle, we have invested a lot in the human resources of Tanzanians by training locals to understand our processes.”

As well as sourcing local content in its recruitment processes, Lawal is also passionate that the make-up of those recruits mirrors the communities Dangote is part of.

“We have been promoting diversity from a gender perspective,” says Lawal. “We have female drivers and technicians at various levels of the plant. We are developing female engineers in every sector of the business from the production to the packing plant. That speaks to the future of the company, our culture as an organisation and what we stand for as a brand.”

The future of the company is clearly at the forefront of Lawal’s mind when we speak with him.

“The future is very promising,” he tells us. “There is capacity for 3 million metric tons per annum at the plant. We are currently doing 2 million metric tons per annum. We have not been able to meet that redundant capacity of 1 million metric tons yet, but once we can expand our fleet size it will give us the ability to enter more of the market while growing our presence internationally.”

Lawal is also optimistic about a new rail link the government is trying to run into Mtwara Port.

Lawal is also optimistic about a new rail link the government is trying to run into Mtwara Port.

“It will give us the opportunity and ability to get materials in and out along the rail from the other side of the country, which will significantly improve our capabilities,” says Lawal. “We will also be introducing barges that will support deliveries to the northern markets, giving us better visibility for both clinker and cement.”

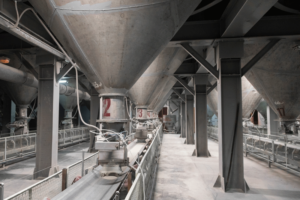

As well as introducing a dual-fuel fleet, Dangote Cement Tanzania has also invested in a more sustainable future through an integrated power plant that produces 50 MW of electricity.

“It is not yet at full utilisation,” Lawal points out. “That means the company has the potential for future growth capacity, selling into the Seychelles and Madagascar markets and more countries that can use our cement. Countries like Rwanda have very limited deposits of limestone, so we will have more clinker to export out to those grinding plants. There is definitely a bright future.”