For more than 40 years, DRG Technologies label products have helped companies across multiple industries — from automotive and aerospace to household products and electronics— provide identification, instruction, and differentiation for their products.

Headquartered in Arizona, DRG today manufactures from two locations, Safford and Chandler, with additional logistic and distribution facilities in Mexico.

The company offers a complete portfolio from durable UL labels, insert cards and tags, packaging and speciality labels, to security and tamper-evident solutions and more. The products meet the most stringent quality requirements with regard to multiple certifications.

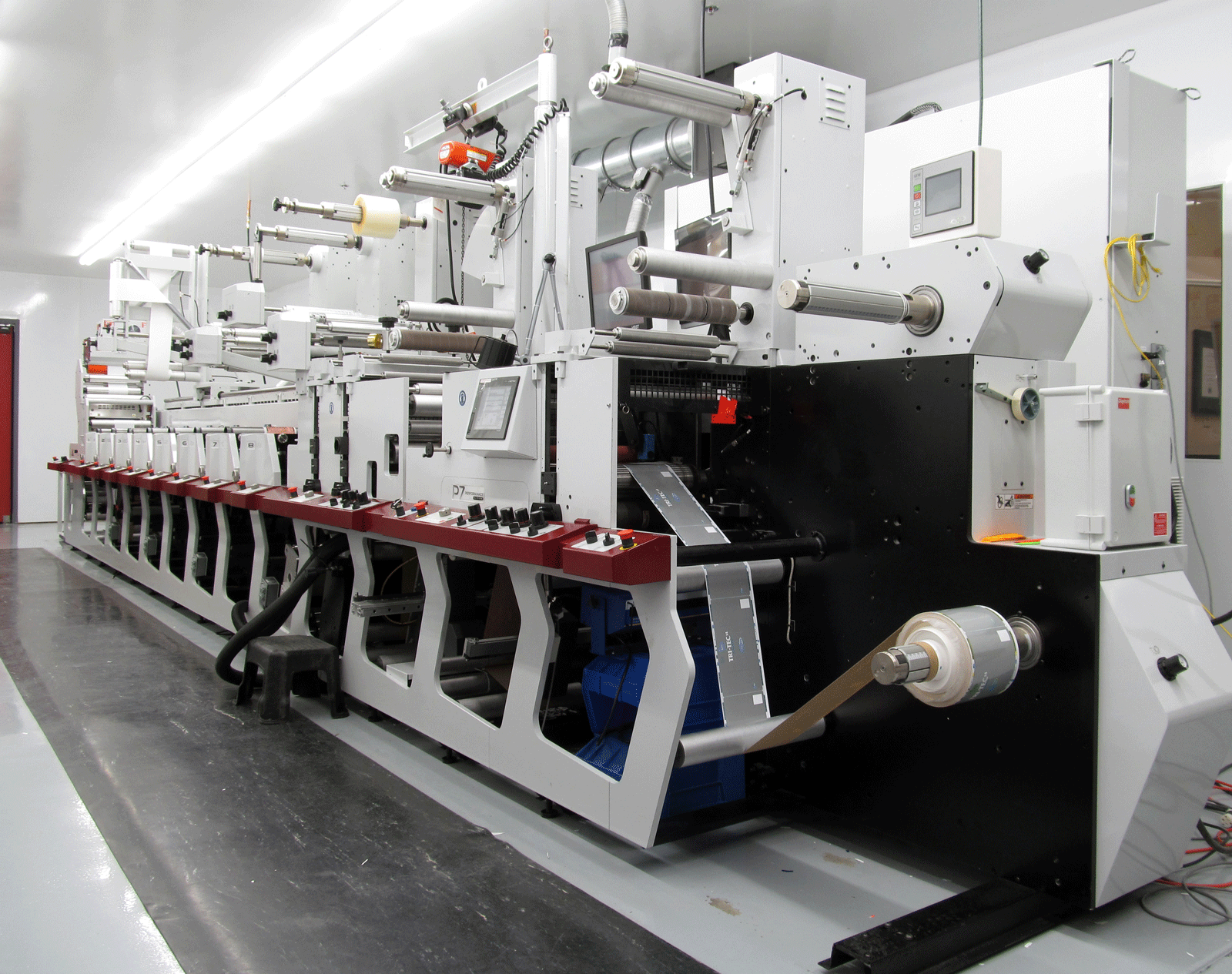

“We provide complete label and tag solutions, offering a broad-based spectrum of products, aiming to be the one-stop-shop for our customers,” said Roger Popovec, President of DRG Technologies. “We have three different printing capacities – flexographic print, as well as screen print and digital print, something which allows us to consolidate vendors. Many large, diverse companies appreciate being supplied from a single source which can meet all their varied requirements.”

“We provide complete label and tag solutions, offering a broad-based spectrum of products, aiming to be the one-stop-shop for our customers,” said Roger Popovec, President of DRG Technologies. “We have three different printing capacities – flexographic print, as well as screen print and digital print, something which allows us to consolidate vendors. Many large, diverse companies appreciate being supplied from a single source which can meet all their varied requirements.”

DRG provides many innovative ways to help reduce costs and add value, including but not limited to, engineered solutions, vendor-managed inventory and just-in-time fulfilment. DRG works closely with their customers to identify and design a customized solution that fits their needs.

“We can accommodate requirements for very low as well as very high volumes – a feature that distinguishes us from many competitors, “ noted Mr Popovec, explaining that DRG Technologies is primarily a custom printer. “We do have a couple of stock items, but 95% of our products are specifically printed for customers. In addition, we offer a high level of service and inventory management programmes that allow for just-in-time delivery to our customers within hours of receipt of the work.”

Sustainable solutions

New, innovative products for the RPC industry have been added recently to the company’s portfolio. “In the US, reusable plastics containers are the primary methods for carrying produce between the fields, the processors and the grocery stores. RPC labels play a crucial role in the efficiency and sustainability of supply chain operations. Standardizing RPC labels ensure that products are correctly labelled, accounted for, and tracked throughout their journey,” explained Mr Popovec.

In collaboration with IFCO, a leading supplier of reusable packaging containers; fresh produce growers; and Avery Dennison, a labelling and functional material developer, DRG has developed cost-effective labels that are completely removable during sanitation, ensuring that RPCs are clean and residue-free. This ensures the RPCs are left in perfect condition for their future use.

The new label, made from paper, has undergone extensive field testing by IFCO and DRG across several different commodity and pack types where film labels are currently being used, including field, shed, and cooler. The new label has shown equivalent functionality to film in those environments, providing growers and packers with a reliable labelling solution.

“We offer a comprehensive RPC labelling solution. Our RPC labels are constructed using materials designed to withstand harsh environments and temperature variations, ensuring that the product’s label packaging remains intact throughout its lifespan. Our newest label development has been tested and leaves no residue after the sanitation process. This avoids further costs associated with cleaning the RPC’s and improves the quality and lifecycle of the RPC.”

In addition, Mr Popovec noted, “The newest RPC label development reflects the increased focus on more sustainable solutions. As a paper solution it can be more recyclable than a plastic film label, another standard solution in the RPC industry.”

Beyond the RPC solution, he affirmed that the company has taken a proactive approach to sustainability – DRG has registered as a FSC (Forest Stewardship Council) facility, which means they can provide their customers with a full chain of custody certification on many of its critical products.

Expanded capability

Expanded capability

It is not only DRG’s own portfolio that has expanded. The company has recently achieved a major business growth milestone, when in May 2023 it announced the acquisition of La Fiesta Label & Packaging Systems, a renowned provider of labelling solutions based in Chandler, Arizona.

The acquisition will expand DRG Technologies’ product portfolio with the addition of shrink sleeves, flexible packaging, digital, expanded board stock, and strengthen its presence in the labelling and packaging industry. With this acquisition, DRG Technologies will have access to La Fiesta’s technology and expertise, enabling the company to offer a wider range of labelling solutions to its customers.

“We are excited to welcome La Fiesta Label & Packaging Systems to the DRG Technologies family,” said Roger Popovec. “La Fiesta’s expertise and innovative products will complement DRG’s existing portfolio and help us to better serve our customers with advanced labelling solutions.”

In growth mode

The acquisition will also allow DRG Technologies to expand its presence in key markets and provide enhanced customer service to its clients, and the two companies will now work together over the coming months to integrate their operations and products, with no disruption to customer service during the transition.

Mr Popovec affirmed that despite the current market challenges such as continuing supply chain disruptions and rising inflation, the company remains in growth mode. “We have a strategic plan to continue to expand the business. We’re making substantial investments in the business, both in new technologies and resources to further strengthen our product offering and capabilities. We are 100% privately owned and self-funded, and our market position is sound.”

“With the acquisition, we have gained specific capacities and capabilities that we did not have before. We will be able to continue to grow the business by leveraging the expertise and the teams in both facilities and promote cross-functional sales growth from existing as well as new customers,” he concluded.